Request a Free Sample – https://www.procurementresource.com/production-cost-report-store/acetyl-tributyl-citrate/request-sample

What is Acetyl Tributyl Citrate?

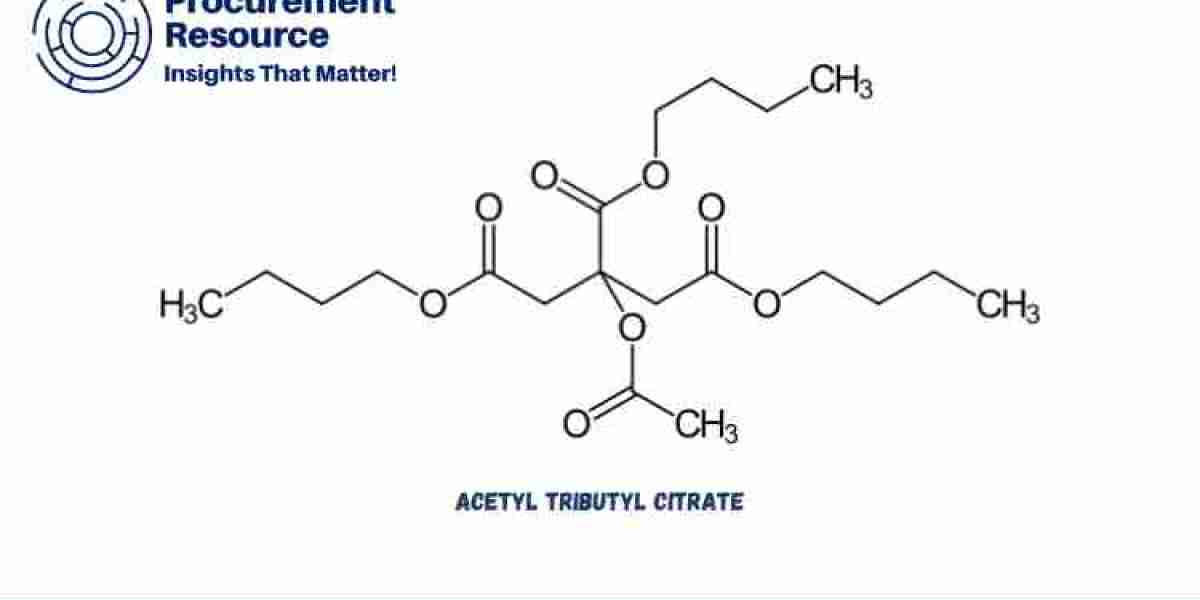

Acetyl tributyl citrate (ATBC) is a chemical compound produced by esterifying citric acid with butanol. It is a colourless and odourless liquid that has low volatility and is known for its plasticizing properties. These attributes make ATBC an ideal component in the production of medical devices, food packaging materials, and other polymer-based products that require a safe, non-toxic plasticizer.

ATBC has gained significant popularity due to its environmental benefits, as it is biodegradable and free from harmful chemicals like phthalates. It is considered a safer alternative, particularly for applications in the food and medical sectors, where safety and non-toxicity are critical.

With the increasing demand for eco-friendly and sustainable products, the global demand for ATBC is expected to continue rising. Consequently, understanding the acetyl tributyl citrate production cost is essential for companies involved in its manufacturing process.

Key Factors Influencing Acetyl Tributyl Citrate Production Cost

The cost of producing acetyl tributyl citrate is determined by a variety of factors, each of which plays a significant role in the overall economic feasibility of manufacturing. From raw materials to logistics, these elements affect the cost structure and profit margins for ATBC manufacturers.

1. Raw Material Costs

Raw materials constitute a large part of the acetyl tributyl citrate production cost. The primary raw materials required for ATBC production are citric acid and butanol. Citric acid, a naturally occurring organic acid, is widely produced from sources like sugar and molasses, making it readily available. However, the price of citric acid can fluctuate based on the availability of raw materials and the costs of production.

Butanol, on the other hand, is a more expensive raw material and is derived from petroleum-based sources. As a result, fluctuations in global oil prices can significantly impact the cost of butanol and, consequently, the acetyl tributyl citrate production cost.

The overall cost of raw materials can also be influenced by procurement strategies. Manufacturers who have long-term contracts with suppliers or use alternative sourcing methods may be able to secure more stable prices, mitigating the impact of market volatility.

2. Labor Charges

Labor charges are another critical component of the acetyl tributyl citrate production cost. The production of ATBC involves complex chemical processes that require skilled operators and technicians. Labour costs can vary based on factors such as geographic location, labour laws, and the level of automation in the production facility.

In regions with higher wages, such as North America or Western Europe, labour costs may make up a larger portion of the production expenses. In contrast, countries with lower labour costs, such as parts of Asia, may offer more competitive pricing advantages for manufacturers.

Automation in the manufacturing process can reduce the need for manual intervention, thereby lowering labor costs over time. Moreover, automation helps improve the consistency and quality of the product, which is vital in maintaining customer satisfaction and meeting regulatory standards.

3. Energy and Utilities

Energy costs are one of the most significant factors affecting the acetyl tributyl citrate production cost. The production of ATBC involves several energy-intensive processes, including esterification reactions that require high temperatures. As a result, the consumption of electricity, steam, and other utilities adds up to a substantial portion of the total production cost.

Energy costs can vary based on geographic location, energy tariffs, and the source of energy. Manufacturers operating in regions where energy prices are high may need to invest in energy-efficient technologies to reduce operational expenses. For instance, adopting combined heat and power (CHP) systems or process optimisation methods can help lower energy consumption and enhance overall efficiency.

Additionally, water, solvents, and other chemicals are used throughout the production process, further increasing utility costs. As manufacturers strive to reduce their environmental footprint, there is an increasing focus on using renewable energy sources and recycling water and solvents to lower costs and improve sustainability.

4. Logistics and Transportation

Logistics and transportation costs are important aspects of the acetyl tributyl citrate production cost. Once ATBC is manufactured, it must be transported to customers, distributors, or other facilities. The distance between the production plant and the end market, along with the mode of transportation (road, rail, sea), plays a significant role in determining the cost of logistics.

Transportation costs can fluctuate depending on global fuel prices, transportation tariffs, and the efficiency of the distribution network. Manufacturers may find it beneficial to optimise their supply chain by working with third-party logistics providers, consolidating shipments, and negotiating favourable contracts with shipping companies.

Furthermore, raw materials such as butanol and citric acid need to be sourced from suppliers, and the cost of transporting these materials to the production plant also contributes to the overall production cost.

5. Supply Chain Management

A well-managed supply chain is crucial for maintaining cost efficiency in ATBC production. Disruptions in the supply chain—such as delays in raw material deliveries, transportation bottlenecks, or unforeseen market fluctuations—can cause significant increases in production costs.

Strategic sourcing of raw materials and having multiple suppliers can help mitigate the risk of disruptions. Additionally, incorporating advanced supply chain technologies, such as supply chain management software or predictive analytics, can enhance procurement efficiency and reduce procurement costs.

Having a reliable inventory management system is also vital in managing fluctuations in raw material prices and ensuring a steady supply of necessary components.

Acetyl Tributyl Citrate Production Cost Model

The acetyl tributyl citrate production cost model helps manufacturers understand the financial implications of their production processes and identify areas for cost reduction. This model typically includes a breakdown of:

- Fixed Costs: These are costs that remain constant regardless of the production volume, such as the depreciation of equipment, salaries of permanent staff, and plant maintenance costs.

- Variable Costs: These are costs that change based on production volume, such as raw material costs, utilities, and transportation expenses.

- Semi-variable Costs: These costs vary depending on factors like production levels, energy consumption, and overtime labor hours.

A detailed cost model helps manufacturers make informed decisions regarding investment in new equipment, process optimisation, and pricing strategies to maintain profitability.

Pre-feasibility Studies for ATBC Production

Before embarking on large-scale production, manufacturers often conduct pre-feasibility studies to assess the financial viability of their projects. A pre-feasibility study typically involves evaluating capital expenditures (CapEx), operational expenses (OpEx), production capacity, market demand, and regulatory requirements.

This study helps businesses understand the potential return on investment (ROI) and identify any risks that may arise from fluctuations in raw material costs, energy prices, or market conditions. A thorough pre-feasibility analysis is essential for ensuring that the production process is financially viable and can meet demand at a competitive price.

Request a Free Sample

To gain further insights into the acetyl tributyl citrate production cost and access detailed cost breakdowns, we offer a comprehensive Acetyl Tributyl Citrate Production Cost Report. This report includes data on raw material prices, labor costs, energy consumption, and more. Request a free sample of the report to explore in-depth financial analyses and recommendations for improving cost-efficiency in your production process.

For more detailed information or to request Free Sample - https://www.procurementresource.com/production-cost-report-store/acetyl-tributyl-citrate/request-sample

Procurement Resource

Effective procurement is key to controlling production costs for acetyl tributyl citrate. By utilising procurement resources such as supplier databases, industry reports, and cost comparison tools, manufacturers can identify the best sources for raw materials at competitive prices.

Moreover, strategic sourcing and building strong relationships with suppliers can help lock in favorable prices and ensure a stable supply chain. Procurement teams can leverage advanced software tools for better demand forecasting, supplier performance monitoring, and inventory management to enhance operational efficiency

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Numbers:

USA: 1 307 363 1045

UK: 44 7537171117

Asia-Pacific (APAC): 91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA